Plasma Cutters

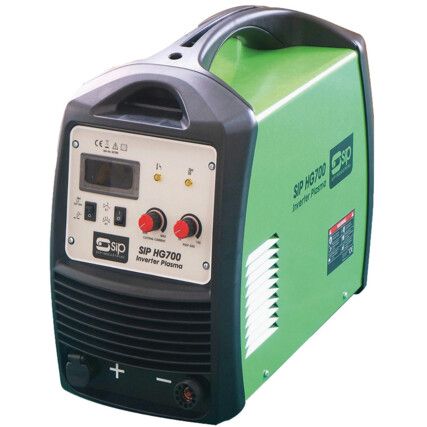

If you need to cut steel, stainless steel, or aluminium easily, quickly, and cleanly, then a plasma cutter is for you. At Cromwell we offer a wide range of plasma cutters usable on materials ranging from thin to thick cutting depths, and available for use in multiple voltage ratings. We offer plasma cutters from popular brands such as SIP®, Parweld®, and Telwin®.

What are plasma cutters?

Plasma cutters are the inverters, pipework, and torches required for plasma cutting. The process of plasma cutting cuts through electrically conductive materials by using hot jets of plasma, achieving a clean and precise cut as compared to abrasives or milling. Oxygen, argon, or nitrogen are popular gasses for

When are plasma cutters used?

Plasma cutters are used when there are both thin and thick electrically conductive materials that need to be cut quickly, cleanly, and efficiently. The most common materials to be cut with plasma cutters include steel, stainless steel, aluminium, brass, and copper. The main industries to use plasma cutters are fabrication, automotive, construction and salvage.

Considerations when choosing a plasma cutter

• Maximum cutting depth - This is an important consideration when choosing a plasma cutter as it will determine the thickness of material that can be cut.

• Voltage - This is the input voltage of the plasma cutter inverter. This determines the environments in which the inverter can be used. 110V is used on site, 230V is used from the mains sockets, whilst 400V is for high power uses.

• Current range - This determines the current or Amps that the inverter can supply. The higher the amps, the thicker material that can be cut.

FAQs

What gas do you need for a plasma cutter?

Gas is needed to use a plasma cutter, as this gas is superheated to become the plasma. The most popular gases used in plasma cutters are oxygen, argon, and nitrogen, although certain other gases may be used. Some plasma cutters feature multi-gas capabilities, allowing for multiple gases to be used where required.

Can plasma cutters cut through anything?

No, plasma cutters can only cut through electrically conductive materials. This is because the conductive materials react to the ionised gas being output from the torch. Materials such as wood, glass, plastic, or poorly conductive metals cannot be proceeded by a plasma cutter.