Welding Table

Welding, whether it be on a large, industrial scale or a smaller, more domestic, hobby based setting, can be rife with safety hazards. Here at Cromwell, we stock the right equipment to ensure that you can be safe when welding. Our range of welding tables are designed to provide a stable and safe work area for you to dedicate to welding. Here at Cromwell, we have a select choice of welding tables from leading brand SIP®.

What are welding tables?

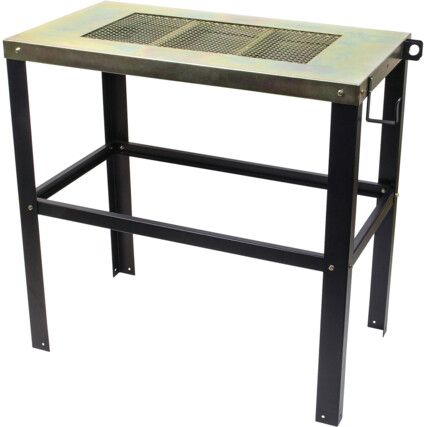

Welding tables are similar to a workbench or worktable in that they are roughly waist high and providing a flat surface upon which to perform small and delicate welding tasks. Welding tables also frequently offer guides to help you measure and square off objects as well as slots for placing clamps or other useful welding equipment whist you undertake your project.

When are welding tables used?

It is advised that when undertaking smaller and more intricate tasks that a welding table is used to achieve optimum results and keep workers safe. Welding tables are suited for squaring or rounding off objects, mounting components to your desired object, measuring, grounding, bending jigs and much more.

Considerations when choosing welding tables

• Load capacity - Welding tables will vary based on the load capacity that they can carry. It's important to check this before purchasing, especially if you know that you'll need to be frequently welding heavy or bulky items on the welding table. The load capacity of a welding table is usually measured in Kilograms (kg).

• Size - In this case, size refers to the surface area of the table top and usually the height of the table itself from the ground when folded out. The height needs to be about waist length for optimum comfort and to help reduce the risk of back ache caused by bending over when welding. Table top sizes vary and can be selected based on your specific needs.

• Foldable - Some, but not all welding tables have the ability to be folded up for transportation or movement around your workshop or work area. It's worth considering whether this would be helpful for your application.

Welding tables jargon buster

We want to make it easy for you to select the right welding table, so here are some key terms that will help you understand the range and features of the products a little better.

What does welding slag mean and why is it good to have a channel in the welding table to collect this?

The American Welding Society (AWS) defines welding slag as "a non-metallic byproduct of the mutual dissolution of flux with non-metallic impurities in welding and brazing processes." To further break this down, welding slag is essentially the hardened layer left on the top of weld made during flux-cored arc welding (FCAW). This product requires chipping off or grinding down between welding passes and thus can cause debris to fall onto your work area.

Having a channel or grate n your welding table to collect this material makes the overall clean-up after you have completed a task easier and more efficiently, which in turn gets you back to working quicker.

FAQs

Why do welding tables have holes?

Some welding tables possess a grate or holes in the table, which allows debris such as slag to be collected and then disposed of to keep the work area clean. Most welding tables also boast slots, which allow for the use of other helpful welding accessories such as clamps, jigs and stops to enhance your welding work.

What are welding tables made of?

Most often, welding tables are manufactured from a steel based material, such as carbon steel or stainless steel. This is due to the materials' excellent resilience, ability to withstand high temperatures which are commonplace when welding, easy clean properties and its conductivity which provides a grounding effect to the table for maximum user safety.