Cutting Wheels

Cutting wheels, also known as cut off wheels or cut off discs are available in a large range of sizes and configurations to perform any cutting task. Commonly used in angle grinders and similar power tools, cutting wheels are an invaluable tool for all kinds of metal fabrication jobs. Cromwell stocks numerous types of tried and tested cutting wheels, from trusted suppliers and brands including 3M, Flexovit, Makita, Osaki and Norton Saint Gobain that are used by professionals around the globe.

What are cutting wheels?

Similar in design to grinding wheels and other abrasive wheels, but different in structure and function - cutting wheels are typically used to grind pieces of metal off a surface or workpiece, resulting in clean, precise, and narrow cuts at 90-degree angles.

Cutting wheels come in a number of configurations, with varying grains, sizes, and diameters to suit the needs of demanding professionals. All cutting wheels are made from strong compounds, bonded together using powerful substances.

Why cutting wheels?

The right kind of cutting wheels provide a tremendous amount of value to industry professionals and hobbyists alike.

The thin design of cutting wheels gives users the most accurate cuts possible. This makes them far more precise and clean cutting than equivalent grinding wheels, or other types of abrasive wheels.

When are cutting wheels used?

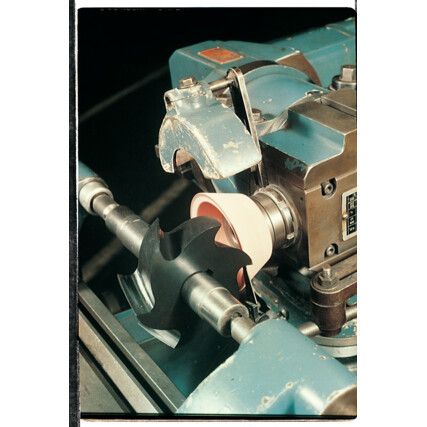

Cutting wheels are used in angle grinders, bench grinders, die grinders, table saws, chop saws, and cut off saws - and are invaluable for use across a large range of industrial applications, but most commonly in metal fabrication.

They excel at making precise and narrow cuts at 90-degree angles on metal bars, sheets, workpieces and more.

Cutting wheel types

There are two main types of cutting wheel - type 41 and type 42.

• Type 41 - is completely flat, making it efficient for general purpose cutting and minimal workpiece interference.

• Type 42 - cutting wheels have a depressed centre, enabling additional clearance when cutting at constrained angles. The dip in the centre means users can utilise a raised hub, which adds added strength and securely holds the wheel in place.

Unsure about the right type of cutting wheel for your applications? Feel free to contact our experts, who offer free, professional advice to help you find the right products for your usage.

Considerations when choosing a cutting wheel

• Wheel material - The material of your cutting wheel is one of the most important considerations when choosing.

Aluminium Oxide is common, cost effective, and highly consistent for use on steel.

Ceramic is tougher and effective for use on harder metals, such as armoured steel and titanium. Ceramic tends to cut cooler than other materials, too.

• Wheel diameter - Cutting wheel diameter dictates the overall RPM of the wheel, as well as the power tool that it's used in. Cutting wheels come in diameters of around 2 - 5 inches for die grinders, 4 - 9 inches for angle grinders, and much larger diameters for large, high-speed cutting machinery such as chop saws.

FAQs

What cutting wheel for tile?

A diamond or ceramic blade used in an angle grinder is best for cutting tile. Always check with the wheel manufacturer for a list of suitable cutting materials.

Can you cut aluminium with a cutting wheel?

Aluminium oxide cutting wheels with a grit range of 60-40 can be used on aluminium.