Grinding Wheels

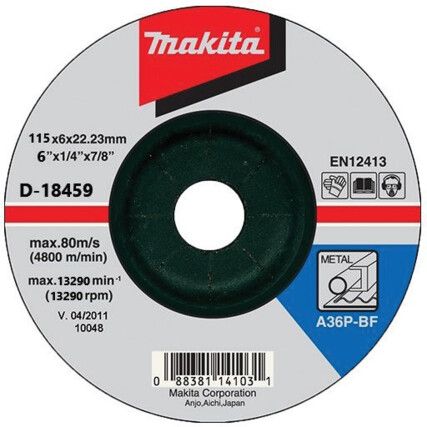

Find precision, high-quality grinding wheels online at Cromwell.co.uk. We stock a wide choice of shapes and sizes to suit all your grinding needs from market-leading brands like 3M™, Makita®, Pferd® and Master Abrasives®.

What are grinding wheels?

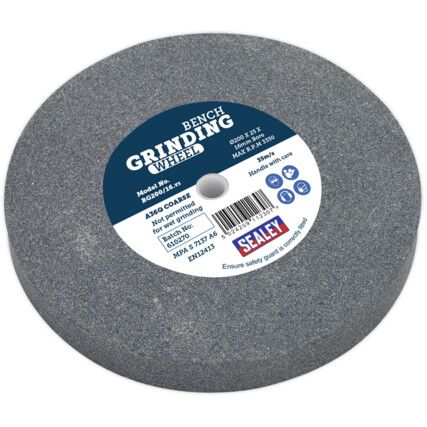

Grinding wheels consist of a steel disc coated in layers of bonding material, abrasive grains, and fibreglass. They're available in three common shapes:

• A straight profiled snagging wheel is the smallest of the grinding wheels and is used exclusively with high-speed die grinders.

• A straight profile with a depressed centre which allows for grinding angles between 0°-45°.

• Depressed or saucer-shaped grinding wheels which allow for grinding angles between 0°-30°.

When are grinding wheels used?

Used in grinding and machining operations, grinding wheels grind and shape metal and are fitted onto a bench grinder, angle grinder or a high-speed die grinder.

Grinding wheel types

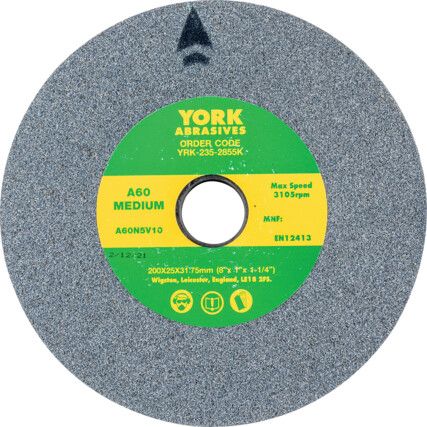

There's a wide selection of grinding wheel sizes available on the market. However, it's the abrasive grains bonded to the wheel that provides the finish required. These grains are sized according to coarse and fine applications, and we've detailed some of the most common below.

• Aluminium oxide - This cost-effective grain provides high stock removal and is ideal for use on metals

• Ceramic alumina - Ideal for hard metals such as titanium, this grain micro-fractures and self-sharpens during grinding for a consistent and extended performance

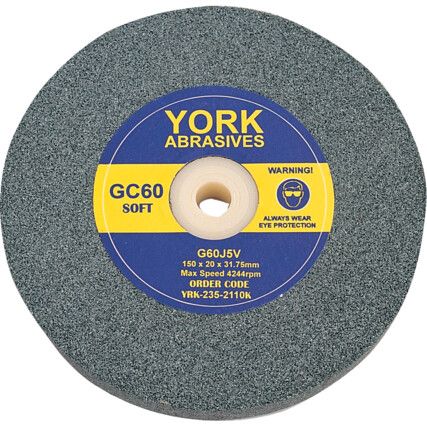

• Silicon carbide - This is a sharp grain that offers fast stock removal, but is short lived due to its friability

• White aluminium oxide - Used for hard-grade steels, these grains are long-lasting and deliver consistent performance

• Zirconia alumina - Performs well in high-temperatures and micro-fractures during grinding for self-sharpening. Ideal for use on steels for fast and consistent stock removal

Considerations when choosing grinding wheels

• Diameter - this should fit easily in place on the tool without the need to remove safety guards. Choosing the correct size protects against injury and ensures the RPM compatibility, which prevents damage to both the wheel and the tool.

• Thickness - a good thickness for a grinding wheel is around 6.35mm. A good thickness will provide enhanced performance and allow for a longer lasting product.

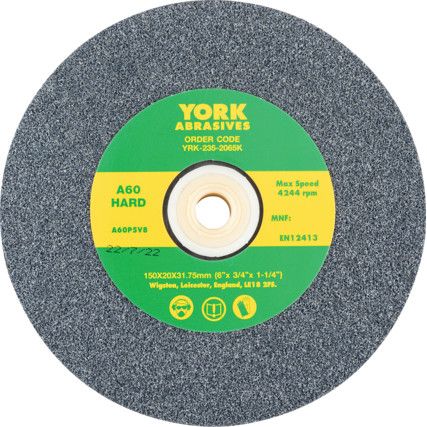

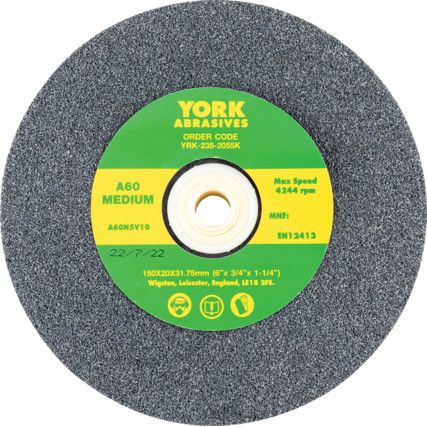

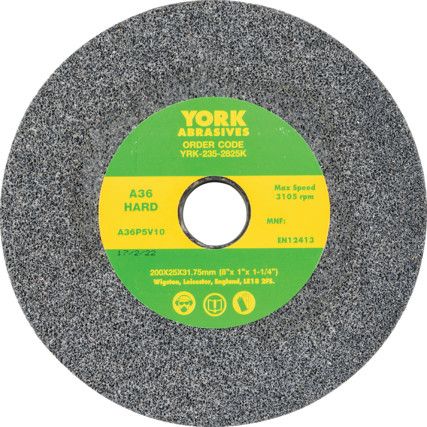

• Grit - choose a grit between coarse to fine depending on the finish you require on the workpiece.

• Bond material - bonding materials come in a choice of hard or soft. Soft bonding exposes new grains quicker than hard bonds and is ideal for smooth grinding applications. Hard bonding offers a longer product life but delivers a coarser finish.

• Abrasive grains - these can consist of a single type or a blend of multiple types and should be chosen according to the material and finish required.

Grinding wheel jargon buster

We want to make it easier for you to find the grinding wheel you want, so we've put together a brief outline of an associated standard to keep you in the know.

What does the standard ISO 6103:2014 mean?

ISO 6103:2014 covers bonded abrasive wheels with a diameter greater than or equal to 125mm and an operating speed of greater than or equal to 16m/s.

This publication outlines the testing methods for measuring unbalances in these grinding wheels, and upholds the acceptable unbalance values for quality testing.

Let's break it down...

• ISO - these standards are outlined and published by the International Organization for Standardization

• 6103 - This is the assigned legislation number

• 2014 - This is the year this standard was last updated. It has since been reviewed and confirmed as current

FAQs

Do I need training to operate a grinding wheel?

Yes. PUWER regulations require that everyone who operates work equipment must be properly instructed trained to do so.

How long do grinding wheels last for?

When used regularly a grinding wheel should provide good results for up to two years.

What personal protection equipment is needed when using a grinding wheel?

Protect the eyes and face from high-speed particles with a visor or face shield coupled with goggles or safety glasses. A visor on its own won't protect the eyes and we recommend wearing safety goggles instead of safety glasses in this kind of application to provide a complete seal for the eyes. Safety gloves that provide good abrasion and cut protection are also recommended to prevent injuries to the hands.

Can grinding wheels get wet?

Keep grinding wheels dry to protect them from corrosion and frost. Made from porous material, once wet they need a long time to thoroughly dry.