Ball Nose Cutters

For the precise cutting of materials, our extensive selection of ball nose cutters (also known as 'ball nose endmills') are just right for the job. Designed to cut deep ribs and slots in moulds and machining deep corners, these tools offer precise and detailed results.

Cromwell stocks a wide range of high-quality ball nose cutters, from trusted brands used by industry professionals around the globe.

What are ball nose cutters?

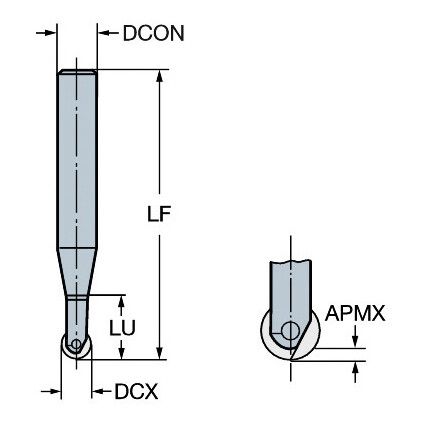

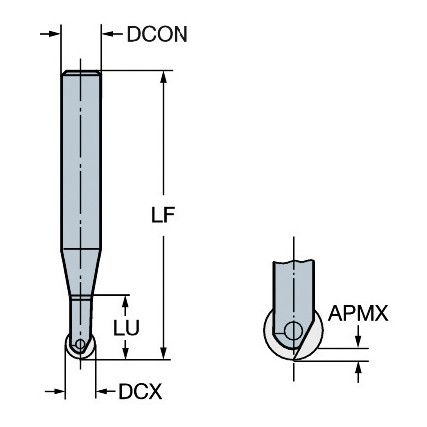

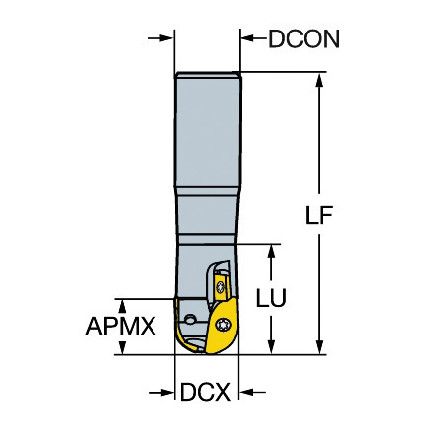

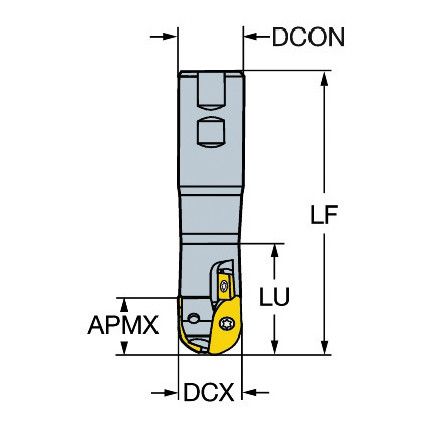

Ball nose cutters - aptly named as the cutter looks like a ball - are used to mill arc grooves and all kinds of curved surfaces in a HMC or VMC machine. The cutters boast a short chip retaining groove on their tip, resulting in a low chip discharge. This makes them excel at cutting curved surfaces on most types of material.

Why a ball nose cutter?

It's no secret that the precision requirements for the tools used in copy milling are incredibly strict. Tight tolerances must be met to avoid manual reworking - particularly when machining the corner radius.

Luckily, the ball nose cutter is designed for accuracy - and when set up correctly, won't cut a fraction of a millimeter out of place. Because their radius is at the bottom, they provide an incredibly fine surface finish, often meaning users won't have to finish the product any further. This saves no end of time during the manufacturing process.

When are ball nose cutters used?

Ball nose cutters are most commonly used for machining 3D contours in the mold and die industries. These precise and handy tools play a huge part in creating contoured 3D shapes of all kinds - for example, manufacturing turbine blades and parts for hydroelectric generators for the energy industry. They are also vital in the:

• Automotive industry

• Aerospace industry

• Medical industry

• Any other die and mould application

If you're looking for the ideal ball nose cutter for your job but aren't sure about the best one for your needs, feel free to ask our experts for specialised advice.

Considerations when choosing a ball nose cutter

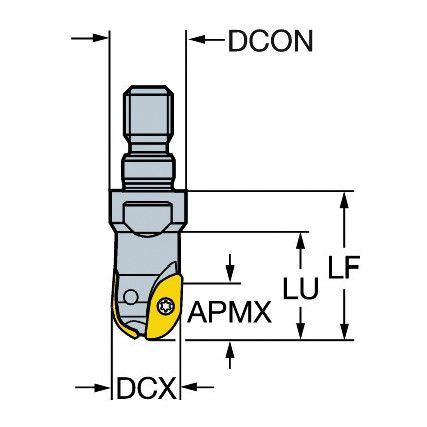

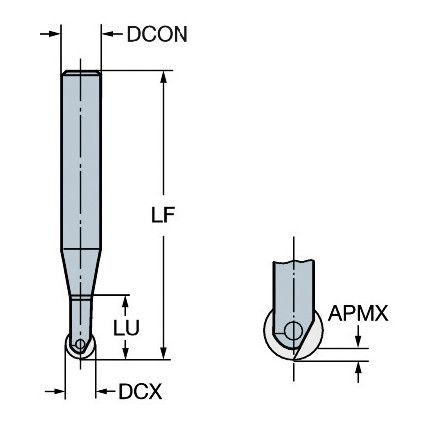

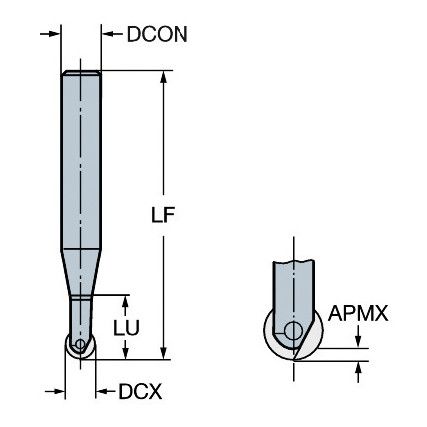

• Cutting depth - Cutting depth can be difficult to get right when purchasing a ball nose cutter. To ensure precision and rigidity whilst avoiding any overhang, choose a cutter length that's just long enough. A standard rule of thumb is to multiply the cutter diameter by five.

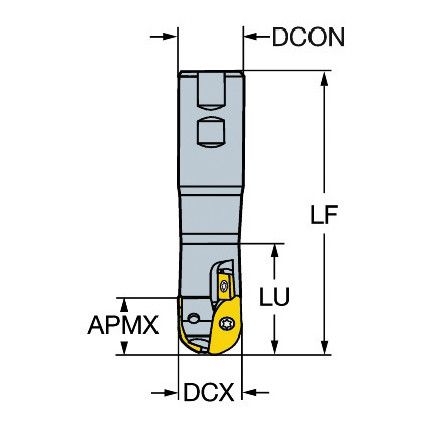

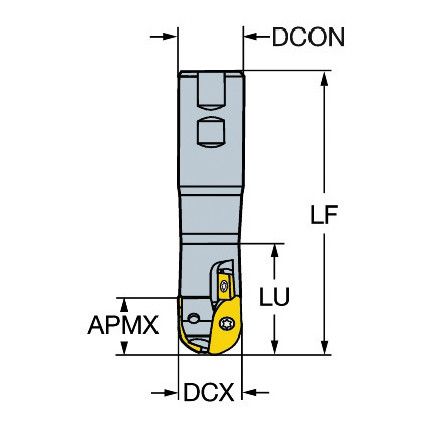

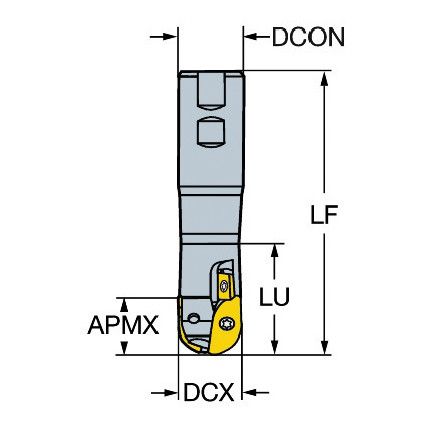

• Cutting diameter - The cutting diameter of a ball nose cutter determines the width of the slot you're able to make. It also affects the amount of chip removed in side milling applications, so ensure you check a suitable diameter to meet your product requirements.

Ball nose cutter jargon buster

HMC / VMC Machines

These are the machines you're likely to use a ball nose cutter in. HMC = Horizontal machining centre, and VMC = vertical machining centre.

Tilt angle

It is generally recommended to use ball nose cutters on a slight incline, or 'tilt'. This prolongs the life of a ball nose cutter by avoiding a '0' SFM condition at the very centre of the tool. It is advised to feed the tool at the angle of the incline where possible.

FAQs

Can I use ball nose cutter for wood?

You can use a ball nose cutter for wood, however the grind on the majority of ball nose cutters are intended for metal cutting over wood. A dedicated carbide router bit has a much more aggressive cutting edge that is better suited for woodworking.

What is a ball nose cutter used for?

Ball nose cutters are used for milling and machining any 3D shape or contour. They are also used for slotting and pocketing.

What materials can I cut with a ball nose cutter?

The ball nose milling cutters we stock are suitable for use with a wide range of materials. If you're dealing with items which are particularly strong, we have options which can cut through stainless steel titanium alloy and Inconel.