Machine Screws

When a firm fastening is a must, machine screws are the ideal product for providing anchoring in industrial and automotive sectors where resilience is a must. Our wide range of machine screws from leading brand Qualfast are manufactured to international and European standards to ensure superior performance when you need it the most.

What are machine screws?

Machine screws are fasteners that are designed specifically for clamping metal parts together in machinery. They are distinguished by their flat tip which requires a pre-threaded hole to be tapped before using the screws as well as a uniform thread which is unlike usual tapered threads that other screws possess. The screws are then threaded through the pre-drilled hole and are tightened with a nut for maximum hold. Machine screws vary mostly in their head shape and driving head type including Pozi, TX, Phillips and Slotted.

Why machine screws?

This type of fastener is manufactured to provide a stronger, more durable joint than other types of screws. Machine screws are designed to withstand vibratory forces and hold fast even when under stress. This makes them ideal for use in engines, large industrial equipment, and general machinery as well as electronics.

When are machine screws used?

Machine screws are most often used in the automotive and industrial sectors, where there is a requirement for an extremely resilient fastener to hold components in place.

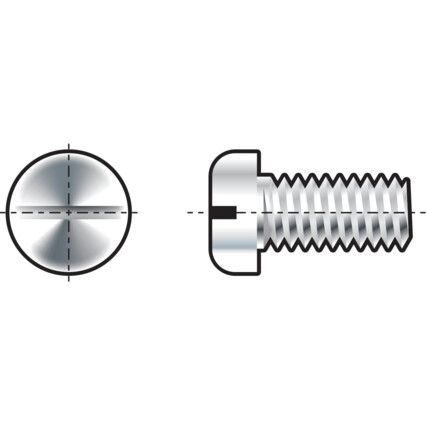

Machine screw head types

The main ways in which machine screws vary from product to product is in the type of head that the fastener possesses. Listed and explained below are the 8 most common types of machine screw head to help you select the right product for your requirements.

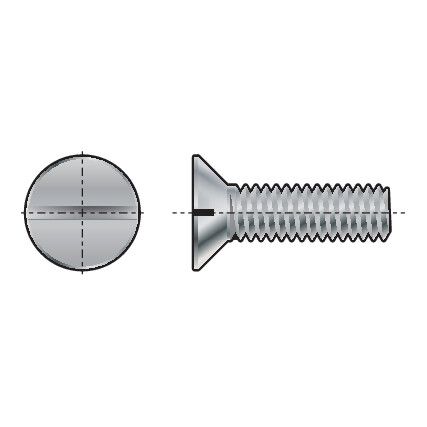

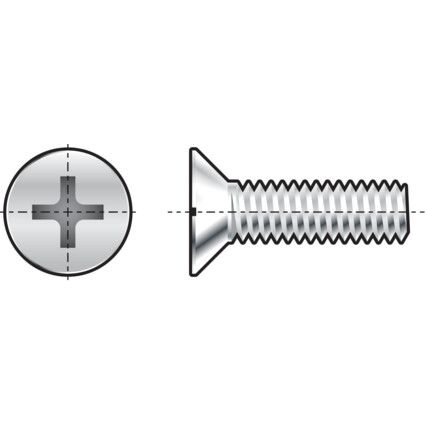

• Countersunk - This head type is flat and specifically designed to sit flush with the surface of your desired material when inserted.

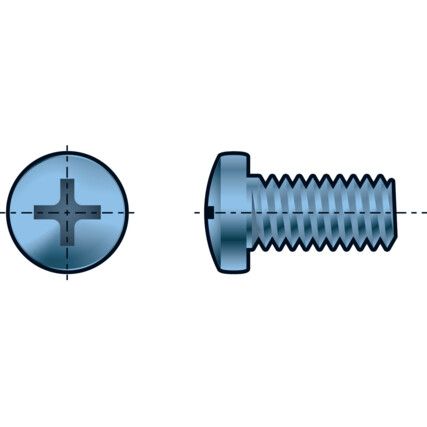

• Pan - Similarly to button head screws, pan head screws have a slightly domed head, however they have straight sides.

• Cylindrical - These screws have a deep set head and a flat disc driving surface.

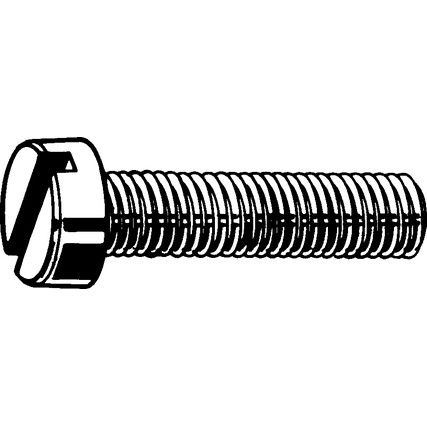

• Raised Cheese - Cheese head type heads are so called due to their resemblance to a wheel of cheese. They are deep set with a flat disc top and straight edges.

• Button - Button head screws have a domed head and curved edges.

• Square - A flat disc top with a square drive type.

• Round - These screws have a domed head that sticks out even when fully inserted.

• Mushroom - Dome headed with a large surface area for a bigger bearing region.

Considerations when choosing a machine screw

• Size - The size of your pre-threaded hole will determine what thread and length size you will need your machine screw to be. Getting the right sized products is imperative to achieve the best grip.

• Material - Most commonly manufactured from steel, brass, aluminium or plastic, it's important to consider what type and what grade of material you require your machine screw to be depending on the level of durability offered.

• Thread Type - Machine screws are generally defined as having either a Coarse (24 threads per inch) or Fine (32 threads per inch) thread type. Fine threads require a greater level of accuracy but provide a higher tensile strength, where Coarse threads can withstand obstructions such as debris and still provide a firm hold.

Machine screws jargon buster

We want to make it easy for you to shop our range of machine screws, so here are some key terms that will help you to make an informed decision about which product is best for your application.

What does DIN, NF, BS and ISO mean?

These letters refer to the governing body that has issued the standard. These tend to be country specific. The most frequently used are listed below to make sure you understand the standards to which our quality machine screws adhere to.

• DIN - Deutsches Institut fur Normung (German Institute for Standardisation)

• NF - French Standards

• BS - British Standards

• ISO -International Standardisation Organisation

FAQs

Will machine screws hold in wood?

Machine screws can be used in wood, however it's worth noting that this is not their intended use. Machine screws are generally designed for working with metal and are thus not the first choice for use with wood. Whilst wood screws are pointed to make easier penetration of the material, machine screws have a flat entrance and therefore can only be drilled into wood by using a threaded insert or a metal tap to create a thread for your machine screw to latch onto.

How are machine screws measured?

Machine screw sizes are normally stylised as Thread Size x Length. If the fastener is metric sized, then the thread size will show the letter 'M' followed by the size in mm that the screw is designed to fit into. For example, a machine screw with an M8 thread size has a shaft that is just under 8mm in diameter and is designed to fit in 8mm holes. The length of the screw is measured from the tip to the top of the threaded section, unless the screw head is countersunk or flat, in which case the length encompasses the tip all the way to the top of the head.