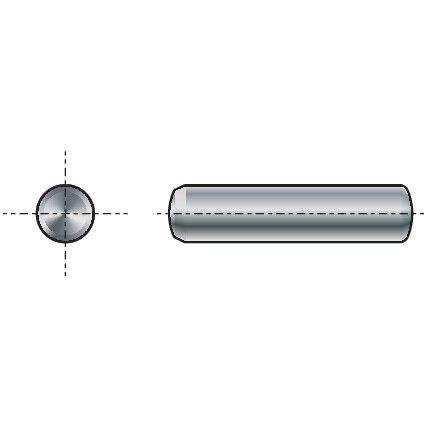

Dowel Pins

Dowel pins are our most popular and simple type of fastener. They are used to ensure precision in a wide variety of industries and applications. Here at Cromwell, we stock a large range of metal pins from suppliers such as Kennedy and Qualfast which are available in a range of lengths.

What are Dowel pins?

Dowel Pins also known as metal pins or engineer's precision dowels are a type of solid cylinder metal fastener that is used to prevent misalignment, locate assembly reference points, fasten workpieces together and ensure precision. They are robust, solid metal rods made from tough hardened steels that are inserted into holes in two or more components to firmly hold and join the components together.

When are dowel pins used?

They are used in many applications to maintain alignment or join multiple components together such as:

• Engineering

• Machinery

• Automotive construction

• Maintenance and servicing functions

• Furniture construction

• Aerospace

• Tool rooms

• Construction

• Workshops

Considerations when choosing a dowel pin

• Length - The length of dowel pin required will depend on the intended application.

• Pin diameter - To ensure a precise fit the pin diameter should be considered before undertaking.

• Leading standard - Dowel pins are made to standard tolerance levels; selection should be made based on the application. Standards include DIN 7, DIN 6325, DIN 7979 D and D1474.

Dowel pins jargon buster

• DIN - Standard drawn up from German Institute for Standardisation

• DIN 7 - Dowel Pins are solid cylindrical pins precision manufactured to a tolerance class of H8 undersized and m6 which is oversized.

• DIN 6325 - Dowel Pins are headless parallel pins ground and hardened to a precise diameter.

FAQ

What is the measurement of H7 tolerance?

H7 (hole) tolerance range = +0.000 mm to +0.025 mm. p6 (shaft) tolerance range = +0.042 mm to +0.026 mm with a potential interference will be between −0.001 mm and −0.042 mm.