Wellingtons

Safety wellington boots provide reliable waterproofing in tough conditions and have evolved to provide extensive safety benefits, including mechanical and cut protection and resistance to impact and puncture injuries.

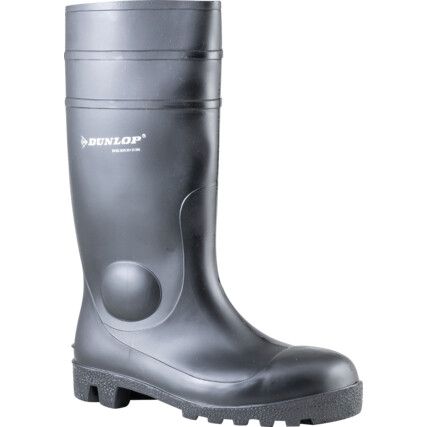

A staple piece of PPE equipment in a wide range of industries, here at Cromwell, we stock a wide selection of safety wellies from high-quality brands like Dunlop®, Adco® and Portwest®.

What are safety wellington boots?

Safety wellington boots are a combination of traditional rubber wellies and compliant safety features, such as a safety toecap and midsole. Fully waterproof with the advantage of protecting up to the lower knee, they're available in a range of designs to suit specific industries and applications.

Why safety wellington boots?

The main advantage of wellington boots is that they are completely watertight. Their design has always been with the focus of keeping the feet and lower legs dry. Couple that with safety features, such as slip-resistance, cold-insulation, oil-resistance and more, and they're the ideal choice for industries where wet and oily conditions are a main feature.

Another benefit of safety wellies is their easy cleaning. They're quick and simple to hose down and spray with disinfectant, which makes them perfect for hygiene priority settings.

When are safety wellington boots used?

Safety wellies are the perfect choice of footwear for a wide range of industries, including construction, agricultural, and automotive. They're available in a range of colours with multiple application features.

For example, white safety wellingtons show up marks and stains to ensure cleanliness and hygiene in food production and medical facilities. While wellingtons used by forestry workers often feature front padding to protect against the slip of a chainsaw.

Safety wellington boot types

Professional wellingtons are widely used in a range of industries, where their waterproofing and extended protection are extremely advantageous. These safety wellies include a safety toecap and midsole as standard, and are CE marked with associated safety standards.

• Agriculture - Used in farming and other outdoor industries, these safety wellingtons are often insulated with a good grip and resistant to chemicals.

• Forestry - This is a standard heavy-duty safety wellington, but often features chainsaw protection at the front of the boot to offer cut protection against saw slips.

• Hygiene - Typically white in colour, these wellingtons are used widely in food production and medical settings. Designed to resist oils and chemicals, this type of boot delivers excellent slip-resistance and can have anti-static features.

• Construction - Designed specifically for use in building and construction, these boots often feature moulded ribbing on the front, sides and back of the ankle to protect against abrasion and other mechanical injuries. This type of wellington often features a reinforced heel to prevent penetration injuries and can be fur-lined with insulation properties.

• Fishing - Safety wellingtons with a pull-cord closure, or waders that extend to the top of the thigh are often worn in this industry. Grip, resilience and waterproofing is a priority in this design.

Considerations when choosing safety wellington boots

• Hazards - a risk assessment will inform the safety characteristics required for the setting.

• Fit - wellingtons should be fitted in the same way safety shoes are fitted to ensure comfort and optimum safety.

• Toecaps - just like safety shoes and safety boots, toecaps are available in traditional steel, composite or aluminium according to user preference.

• Midsoles - depending on the application, a midsole will protect against puncture injuries to the sole of the foot. Alternatively, a digging plate feature absorbs force at the instep during digging tasks.

• Soles - dual density or single density depending on application requirements. Available in a wide range of materials, each with its own benefits and advantages.

Safety wellington boots jargon buster

Safety standards, especially those associated with safety wellingtons and other safety footwear can be a minefield of information. So, we've broken down and explained a key standard to help you choose the best wellingtons for the task.

What does the footwear standard EN ISO 22568-4:2021 mean?

EN ISO 22568-4:2021 outlines the requirements and testing methods for composite midsoles used in safety (PPE) footwear. Composite midsoles, like their steel and aluminium counterparts, must resist puncture force of up to 1.100 Newtons to protect the feet against protruding nails and other sharps.

Let's break it down...

• EN - This is a current European standard

• ISO - The International Organisation for Standardisation publishes, amends and updates international safety standards

• 22568 - This is the assigned legislation number

• -4 - This is the section of the legislation that refers specifically to composite, or non-metallic midsoles

• 2021 - This is the year the safety standard was updated and supersedes the 2019 version

FAQs

Are neoprene wellies safety wellies?

Neoprene is a synthetic polymer that's used widely in wet suits and fishing clothes. It performs well over a wide range of temperatures and repels oils and liquids. While it can be used as a lining to some safety boots, a neoprene wellington will not protect against mechanical risks and is therefore never used to make safety wellington boots.

Can I get safety wellington boots with ankle support?

A lot of safety wellies designed for use in construction and other tough environments feature ankle support. In some cases, the boot has denser material around this area to support the ankle. While other safety wellies feature ribbed patterns that cover the front, sides, and back of the ankle and extend up the shin to reinforce the area to protect against mechanical risks and prevent over-extension.

For more information on safety footwear see our Safety Footwear Guide... https://www.cromwell.co.uk/info/safety-technical-safety-footwear