Anti-Fatigue Matting

Used for reducing stress on the joints and circulatory system, anti-fatigue matting supports workers who are stationary on their feet for long periods.

Of course, one mat isn't equal to the other, and there's a wide variety of types to suit different needs. Anti-fatigue matting can be purchased in different shapes and sizes to suit the desired location, but it's the features and associated benefits that make the difference of the right mat for the right place.

Those who use standing desks in offices, or who work with electrical equipment will benefit from ESD or switchboard anti-fatigue matting. Switchboard matting protects against electric shocks, while ESD matting is categorised into three different types: Electrically conductive, static dissipative and anti-static.

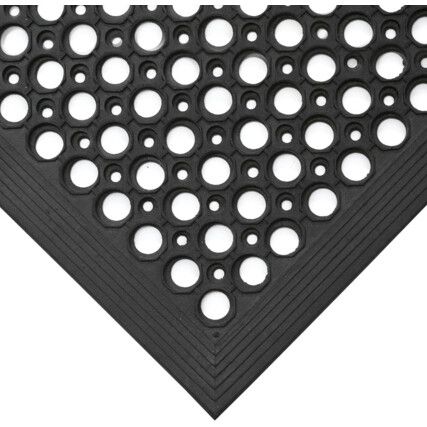

For chemical handling or oily and wet environments, heavy-duty designs are the best. These feature floor traction to prevent the mat from slipping, and have a textured, ribbed or holed surface for anti-slip and spill dissipation to keep liquids away from the user.

Cromwell stock a huge range of anti-fatigue matting from leading brands like Coba Europe® and our own brand, SiteSafe®. For help choosing the best anti-fatigue mats for you, ask our experts. We have a friendly and reliable team who can support and advise with any technical information you need.

What is anti-fatigue matting?

Anti-fatigue mats cushion hard flooring and evenly distribute the user's weight to reduce pressure points and joint pain. The flexible materials used for the matting encourage micro-movements, which stimulate blood flow and prevent blood pooling in the legs, which causes fatigue and long-term health problems.

Why anti-fatigue matting?

Use of anti-fatigue matting has an extremely positive effect on the health and safety of workers. Along with a reduction in the health issues associated with long-term standing, workers see improvements in their posture, while businesses see productivity soar and days lost to sickness reduce.

Many anti-fatigue mats are oil-repellent and made from anti-slip materials, like natural rubber. Tapered edging also helps to prevents trips and falls, which contributes to a reduction in accidents at work.

When is anti-fatigue matting used?

Any job which involves standing on hard flooring for long periods will benefit from the use of anti-fatigue matting. Packers and production line workers often use light to medium-duty mats, while similar matting used for retail workers and those in the catering industry promote better overall health.

In the industrial sector, workshops and warehouses are catered for with heavy-duty, industrial rubber matting. These durable variations are designed for heavier working environments, and feature an anti-slip backing with holes to keep oil spills away from the user.

Anti-fatigue matting types

Anti-fatigue matting is available with a range of features to suit different workloads and environments. They can be made from a wide range of materials, however, the most used are:

Foam-based matting - Ideal for light to medium-duty areas, which are dry and free from liquid spills

Vinyl-based matting - Tough for heavy floor traffic, but comfortable and easy to clean

NBR Rubber matting - High-density and durable for heavy-duty areas. Oil-resistant and non-slip

Considerations when choosing anti-fatigue matting

• Environment - The best mat for dry, medium-duty locations will be no good in a heavy-duty, oily setting.

• Finish - Mats with ribs or holes ensure oil and water spills are drained away from the user to protect them from slips and falls.

• Durability - foam-based matting can be wiped down with a damp cloth, while heavy-duty, rubber matting often comes with a warranty.

• Size - Cromwell stocks a wide range of mat sizes to suit the area you want to cover.

Anti-fatigue matting jargon buster

We want to make it easy for you, so here are some key terms that will help you understand the range and applications a little better.

What does the anti-fatigue matting standard DIN 511330 -R10 mean?

DIN 511330 -R10 is a German standard and isn't as complicated to understand as it first appears. It specifies the slip test conducted on safety equipment produced in Germany, including safety shoes and safety boots, and has been adopted across a number of European countries.

Let's break it down...

• DIN - Is the acronym of the German/Deutsch Institute for Normalisation who carry out testing

• 511330 - Number or name of the anti-slip test

• R10 - This is the anti-slip rating taken from the test results and shows minor to moderate slip resistance. Tests are graded between R9 through to R13, where R9 is minimal and R13, the maximum slip-resistance achieved

FAQs

What does tensile strength mean?

The tensile strength measurement appears on a range of products, like cable ties and safety matting. It describes the maximum resistance a material can withstand before breaking.

What is NBR rubber?

Also known as nitrile rubber, NBR rubber is a synthetic derivative of acrylonitrile and butadiene. Unlike natural rubbers, it has properties resistant to chemicals, including oils and petrol, and makes an excellent material for heavy-duty, anti-fatigue matting.

Do anti-fatigue mats really help?

Yes. A study conducted at Loughborough University in 2012 discovered that standing on hard flooring for 90-minutes caused serious discomfort to the legs and feet, and pain and stiffness in the back, neck and shoulders. Use of anti-fatigue matting in this study showed 'statistically significant benefits' in comparison to standing on hard flooring.

What's the science behind anti-fatigue mats?

When standing stationary for long periods, muscles in the legs constrict and limit blood flow. This puts pressure on the circulatory system and causes blood to stagnate and pool in the legs. The flexible nature of anti-fatigue mats encourages micro-movements while the body balances itself, which stimulates the muscles and regulates blood flow for normal bodily function.