Flap Discs

Flap discs are an efficient alternative to a standard grinding disc. Cromwell stocks a wide variety of flap discs from brands like Sia Abrasives, 3M® and many more, so you can be assured of finding a quality disc for your grinder.

What are flap discs?

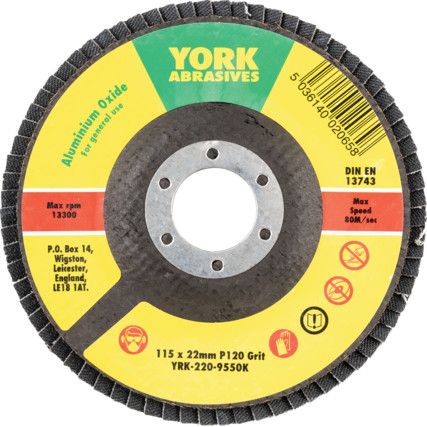

Flap discs are abrasive discs that come in a variety of sizes with both flat and conical designs. The feature a pattern of flaps that overlap resembling corrugation glued to a backing plate, typicall made of fibreglass, plastic or nylon. They are designed for right-angle grinding applications and can remove stock quickly and more efficiently. They are also handy as they can perform grinding, blending, and finishing in a single disc.

Why flap discs?

Flap discs can remove up to five times the stock than a standard grinding wheel, they also produce a smoother finish with less gouging. Their ability to perform multiple applications without changing discs means that there is less downtime, they also produce less noise and lower vibrations than standard discs.

Types of flap discs

• Conical - The ideal choice for removing stock quickly, their conical shape also allows for working on the edge of the disc to increase pressure for higher rates of removal, as well as avoiding damage from contact with the grinders hub.

• Flat - Flat discs offer higher rates of control, which makes them more suited to fishing tasks. There is the added disadvantage that their small sizes might allow the grinder to come into contact with the workpiece, however if caution is taken, they are the best at producing finer finishes.

Considerations when choosing a flap disc

As well as the type of disc there is the consideration of what grit to use with what surface.

• Ceramic - Ceramic grits have a very hard structure and is even self-sharpening. As a result, ceramic grits stay sharper for longer making them highly effective. They also cut at a cooler temperature due to how quickly they cut, meaning they help reduce glazing.

• Zironia alumina - These grits also have self-sharpening properties, giving them a good working lifespan. They are ideal for heavy high performance grinding jobs on metals such as carbon and stainless steels.

• Aluminium oxide - Aluminium oxide is ideally used for grinding steel but can also be used on high tensile aluminium and bronze alloys.

• Coarseness - as with traditional grinding discs, flap discs come in a range of grades from coarse to fine, with coarse grades being suitable for roughing and finer grades for finishing applications.

• Size - Be sure to pick the correct sized disc for your grinder, flap discs typically come in the following sizes 4 ", 4½ ", 5 " and 7 ".

FAQ

How long do flap discs last?

This depends really on the frequency of use and the type of grit. Ceramic flap discs tend to be highly durable as they self-sharpen, meaning they don't loose grinding efficiency as much. However, like all grinding discs, flap discs have an expiry date as the resin used to hold the grit degrades over time. Using the disc after the expiry date is highly dangerous.

Are flap discs dangerous?

Like all powered abrasives flap discs can be dangerous. It is strongly recommended that you wear appropriate PPE including protective eyewear when performing grinding applications with a flap disc. Even in the most skilled hands accidents do happen, a broken flap disc has the potential to jettison itself at 180 mph, so care should always be taken during operation.