Spring Washers

From well-known brands such as Qualfast®, we stock a range of different sizes, with various diameters and washer thickness.

What are spring washers?

Spring washers, also known as locking washers, are shaped to prevent them from resting flush against surfaces without any load on them. By providing an axial load that counters vibrations, they provide spring force and absorb shock, preventing fasteners from loosening over time.

When are spring washers used?

A spring washer provides controlled reaction for dynamic loads in assembly applications. They eliminate rattle, maintain assembly tension, and absorb shock loads. Spring washers are suitable for any industries that involve high-vibration machineries such as electrical, industrial, oil and gas, and valve applications.

Considerations when choosing a spring washer

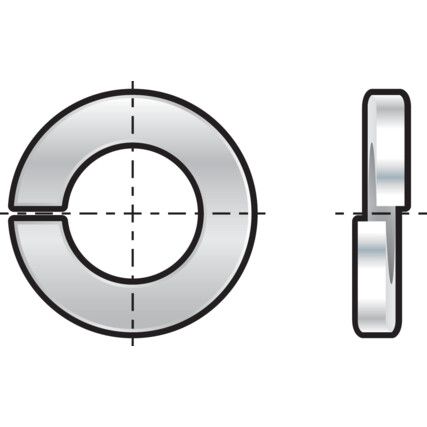

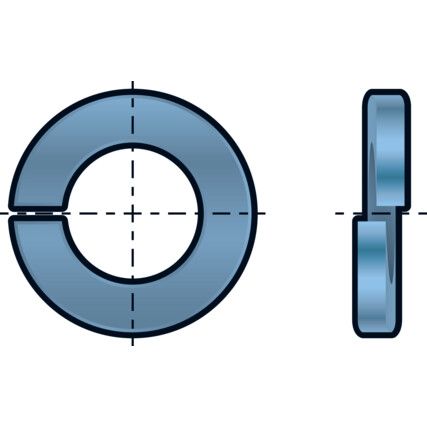

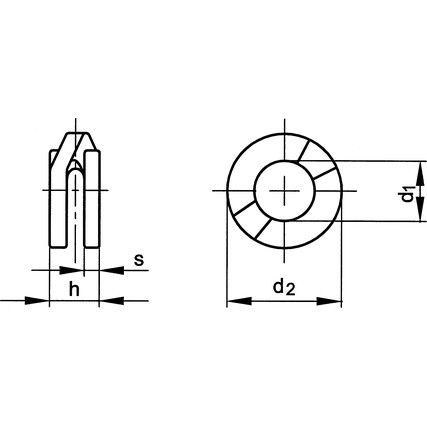

• Type - there are two types of spring washer available; square and rectangular section, referring to the shape of the split end section.

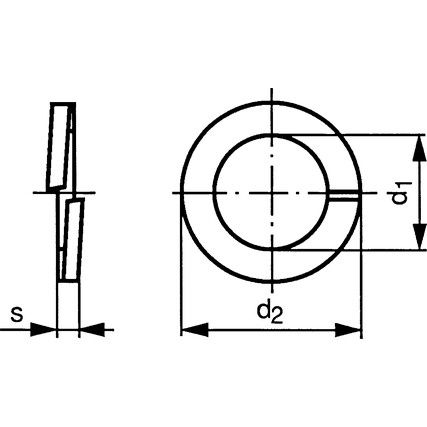

• Dimensions - ensuring you have the correct dimensions of a spring washer is essential for a successful implementation.

• Material - the most common types of material for spring washers are spring steel and stainless steel, but you can also come across aluminium, nickel base alloy and many others. Fastening strength is affected by the material, which prevents it from breaking down.

Spring washer jargon buster

We want to make it easy for you, so here are some key terms that will help you understand the range and applications a little better.

What does the spring washer standard DIN 7980 mean?

DIN 7980 specifies the international standard for spring lock washers with square ends.

Let's break it down...

• DIN - this is the standard drawn up at the German Institute for Standardisation in Berlin that sets unified standards for products and processes.

• 7980 - This is the section for spring washers with square ends. DIN has multiple sections in order to categorise related products and processes.

FAQs

What is the difference between a spring washer and a flat washer?

By increasing the surface area, flat washers help distribute the force of tightening the nut. If a bolt is too long, they can also be used as spacers. In contrast, lock washers are typically used on the nut side of the fastener. Vibration tends to loosen nuts, so lock washers are frequently used in these situations.