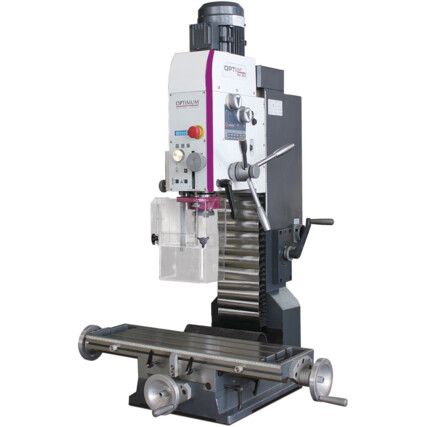

Milling Machines

For quality machining browse our selection of milling machines online now at Cromwell.co.uk. We stock high-quality milling machines, including turret milling machines and mini milling and drilling machines from well-known brands, Osaki® and Excel®.

What are milling machines?

Milling machines, sometimes called drilling machines, use a cylindrical rotary cutting tool to remove material from a metal workpiece. Used widely to make components for aerospace and the automotive industry, they're also used to machine tools and moulds.

Why milling machines?

Milling machines ensure precision when drilling workpieces. They come in different types and in a range of sizes to suit most workplace settings. They can be extremely large industrial machines or micro-sized machines that work well in smaller workshops.

When are milling machines used?

Milling machines are widely used to make components for aerospace and the automotive industry, they're also used to machine tools and moulds.

Milling machine types

Milling machines come in different types and in a range of sizes to suit most workplace settings. They can be extremely large industrial machines or micro-sized machines that work well in smaller workshops.

• Bed type milling machines - On a bed mill the worktable sits on the bed of the machine instead of on top, and the lack of a knee in their design only allows for longitudinal movement

• C-frame milling machines - Typically used for industrial milling, these mills are driven by hydraulics for a powerful performance

• Column milling machines - One of the most commonly used milling machines, a column mill utilises a vertical drill or column. The knee moves the workpiece up, down or tilts it vertically

• Horizontal milling machines - This versatile type of milling machine uses a range of milling tools including disc cutters, forming cutters and the common cylindrical milling tool. Its capable of making inclined cuts and grooves and gets its name from its horizontal placement on the ground

• Planer-style milling machines - Similar in design to a bed type milling machine, the planer mill is compatible with a wide range of cutting tools and head components, so offers more milling options

• Tracer controlled milling machines - A tracer head stylus follows the lines of your template and sends those coordinates to the mill which cuts a perfect copy

• Turret milling machines - Another versatile milling machine, this type allows for the relocation of the table and spindle to offer a wider range of milling options

• Vertical milling machines - Widely used for precision milling, the vertical milling machines use long, thin cutting tools compared with their horizontal counterparts. Their main feature is the vertical spindle that sits centrally on the machine where the cutting tool is mounted and pivots against the workpiece.

Considerations when choosing milling machines

• Type - this will be dictated by the type of milling required and the frequency of its use.

• Size - milling machines are available in a range of sizes including benchtop, full-sized and even micro-sized.

• Cutting capacity - essentially this is the speed of the cut a machine can make and will determine the power it needs and the finish of the piece.

• Spindle depth - this determines the amount of material removed from the workpiece with each pass it makes.

• Table travel - as discussed above, this will be different depending on the machine, with some machines maintaining a stationary workpiece, while others can be repositioned to achieve a wider variety of cuts.

Milling machine jargon buster

To keep you up to date with power tool standards, we've outlined a quality standard for milling machines to help you better understand our range.

What does EN ISO 1701-1:2004 mean?

EN ISO 1701-1:2004 outlines the testing requirements for the accuracy of variable height milling tables. This includes the tolerances allowed for both geometric and machining on general-purpose tests and tests performed on horizontal-spindle milling machines.

Let's break it down...

• EN - This is an abbreviation for European Standards taken from the German translation of Europäische Norm (European Norm)

• ISO - The International Organization for Standardization is the independent body that publishes and reviews safety and quality standards

• 1701 - This is the legislation number

• 1 - This refers to the part of the document that refers to milling machines with a horizontal spindle

• 2004 - Published in 2004, this standard was reviewed and confirmed in 2019

FAQs

What's the difference between lathes and milling machines?

While both machines perform a similar function, lathes rotate the material against the cutting blade, while milling machines rotate the blade or pointed tool against the secured, stationary material.

What kinds of metals are used for milling?

The metals most commonly used for milling are steel (all kinds), nickel, brass and softer metals like aluminium.