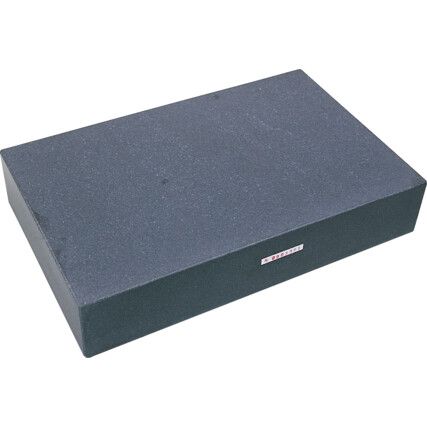

Surface Plates

Buy quality granite surface plates online from Cromwell. We stock a choice of surface plates from well-known brands, like Oxford® to ensure precision construction and performance.

What are granite surface plates?

Granite surface plates and tables are designed for accurate measurement and inspection of products. Shaped and planed to precise measurements, they're provided with adjustable points for levelling to ensure a perfectly flat and even surface.

Why buy granite surface plates?

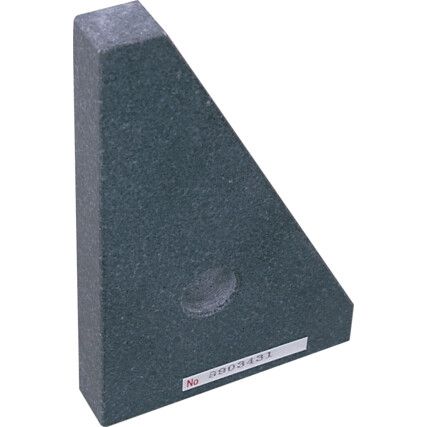

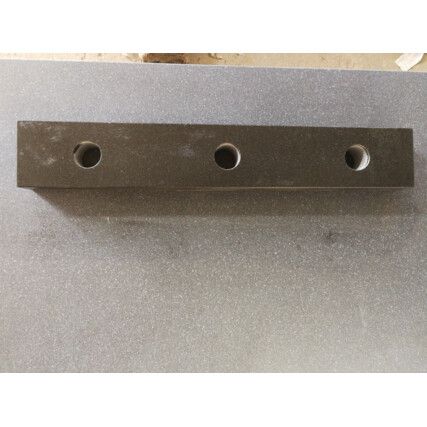

There are many advantages to using granite surface plates. Primarily, granite is a natural and cost-effective material that is extremely hardwearing. When compared to the cast iron alternative, its lightweight and can be calibrated in place. They're non-reflective and chemical and corrosion resistant and can be drilled for different mounting solutions if required.

When are granite surface plates used?

Granite surface plates are used in laboratories and testing facilities to ensure a flat, stable surface when testing a product.

Granite surface plate types

Granite surface plates are available in a wide range of sizes and weights to suit any requirement. To highlight the tolerance of each plate, they're broken down into grades...

• Grade 0 - This grade has a high tolerance of flatness and is widely used in laboratory settings where accuracy for testing is paramount.

• Grade 1 - With a medium level of flatness, this grade is suitable for inspection purposes.

• Grade 2 - This grade has the lowest level of flatness of all the grades and is widely used in workshop settings where this level is acceptable.

Considerations when choosing granite surface plates

• Grade - this depends on your location and the level of accuracy required, with grade 0 being the most precise and grade 2 the least.

• Support stands - depending on the size of the granite plate, metal support stands can be chosen to form a platform, or a metal support bench is often supplied as standard.

• Calibration - most granite surface plates are sold uncalibrated as standard. Suppliers often offer calibration as a separate service.

Granite surface plate jargon buster

Products graded by accuracy are subject to specification standards to ensure each product meets quality requirements for the benefit of the customer. To keep you up to date and informed, we've broken down an applicable standard.

What does BS 817:2008 mean?

This sixth edition standard outlines the dimensions and tolerances required for the construction of rectangular and square surface plates. This standard covers both granite and cast-iron surface plates used for engineering, measurement, and inspection.

This standard applies to the accuracy grades and to calibrated and resurfaced plates. It's a little different to the standards discussed in other articles, as there is also a requirement from the customer purchasing the plate to supply information to and reach agreement with the supplier.

Let's break it down...

• BS - An acronym of the British Standards Institute, which is a governing body responsible for the creation and maintenance of British quality and safety standards.

• 817 - This is the legislation number or name.

• 2008 - This is the date that the sixth edition of this standard was published. It has been updated and supersedes the previous 1988 edition.

FAQs

How often should a granite surface plate be calibrated?

Calibration of a surface plate varies depending on the level of accuracy required and the frequency of the plate's use. Some surface plates are sold uncalibrated and should be calibrated upon installation. For others, recalibration should occur within the first year. However, if the plate is frequently used; the intervals between recalibration should be reduced to reflect this.

What's the difference between cast iron and granite surface plates?

There are a few differences between granite and cast iron surface plates that can make all the difference to your choice of purchase. While cast iron surface plates are strong, they can corrode when exposed to moisture and absorb radiant heat, which creates a risk of burns and prevents repeated use until cooled. In comparison, granite surface plates are corrosion resistant and reflect radiant heat to provide a more durable and usable product.