Drill Drivers

For powerful performance, our range of drill drivers make short work of drilling and screwdriving tasks, to bolster productivity in both industrial and domestic settings.

At Cromwell, we stock a wide choice of drill drivers from well-known, reliable brands, such as Bosch®, DeWalt® and Makita®. Spoilt for choice? Why not ask our experts for help and advice on the best power tools for you.

What are drill drivers?

A versatile tool, a drill driver features two modes, one for drilling and one for screwdriving. The chuck can hold a range of bit types to drill and screw into steel and wood. These drill types often feature a keyless chuck and multiple torque settings to adapt to the task at hand.

Why drill drivers?

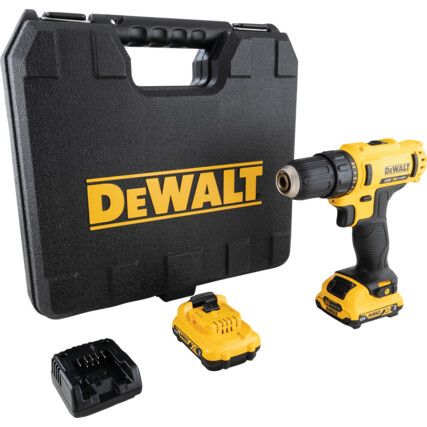

Drill drivers are an extremely convenient tool that allows for a quick setup for smaller tasks. Their compact size makes them ideal in confined spaces, and drill driver sets are often supplied with a carry case, which gives excellent portability to suit a range of trades and DIYers.

When are drill drivers used?

An ideal choice for smaller projects, drill drivers quickly switch between modes to drill and drive screws into a range of materials.

Drill driver types

While most drill drivers are a cordless design for improved convenience, some corded types are still available to suit user preference. Cordless types are often supplied with up to two Li-ion batteries and feature a keyless chuck for quicker loading speed.

Considerations when choosing a drill driver

• Capacity - check the hole capacity the drill driver provides for different materials.

• Torque settings - Take note of the maximum torque settings, as this will dictate the material range you'll be able to drill and screw into.

• Battery - higher voltage batteries will allow for longer running time during projects.

Drill driver jargon buster

There's a lot of technical language used for power tools, so we decided to define the most used phrases for drill drivers to help you navigate our range.

• Brushless motor - uses a permanent magnet to generate rotation instead of current that's driven through wire coils (as is the case with a brushed motor)

• Torque settings - control the rotational power of a drill driver. Higher torque means higher rotation and deeper screwdriving

• Max. free speed - the maximum revolutions per minute of a drill without factoring in drill bits

• Max. chuck capacity - the largest drill bit shank measurement that a chuck can safely hold

• Max. hard/soft torque - Maximum hard torque is the rotational power that the driver will produce when drilling or screwdriving into hard materials, like metal. Maximum soft torque is the most rotational power a driver will produce when working on softer materials, like pine wood.

• Max. drilling - is the maximum size hole a drill driver can make. Sometimes two measurements are given for this based on wood and metal.

FAQs

What's the difference between a drill and a drill driver?

Not much really. Most cordless drills have variable speeds which allow them to drive screws, while a clutch feature senses the tension of a fully driven screw and stops turning.

Can a drill driver go through brick and concrete?

No. Drill drivers are designed for drilling holes and screwdriving into wood and metal. For masonry, a combi drill has the same function as a drill driver, but with the bonus of a hammer drill mode. Similarly, a hammer or impact drill is designed for heavy-duty applications. Make sure to use a masonry bit when drilling brick and concrete.