Indexing Plungers

Indexing plungers are indispensable components when it comes to locking, aligning, releasing and predetermining the movement of machines from one position to another. Choose from an extensive range of min index plunger sizes designed with different heads and styles to suit the needs of you and your industry. Here at Cromwell, much of our stock is manufactured by Ganter© guaranteeing easy, essential and standardised components that allow for optimal usage.

What are indexing plungers?

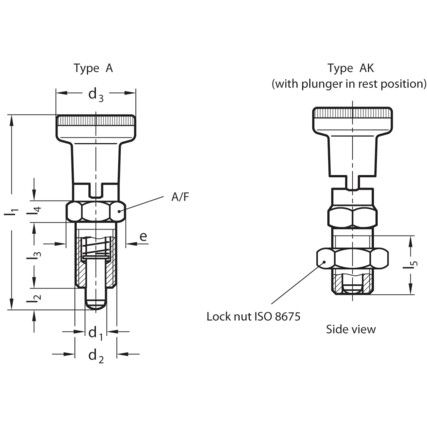

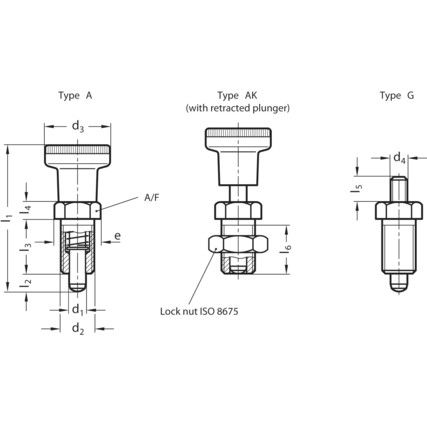

Index Plungers are commonly manufactured from stainless steel to guarantee protection against general corrosion and are a necessary component for machinery that requires operational movement. The device is comprised of a retractable spring body and head for push or pull movement which in turn positions or locks different components of the machinery and equipment into place, usually by locating pre-defined holes and grooves in the mechanism.

When are indexing plungers used?

Indexing plungers are ideal for when a mechanism design requires a locking system and are a general necessity in many industries for machinery that involves any predetermined movement. Whether the design demands a push/pull head for easy engagement, or the min index plunger needs incredibly small dimensions for thin metal and tricky access, Cromwell can provide for whatever the use.

Considerations when choosing indexing plungers?

• Dimensions - For machinery to work at its best, the dimensions of indexing plungers must be accurate. That is why we offer a vast range of sizes and styles. Our site provides exact and detailed product specification to inform the customer on what to expect when they order indexing plungers from Cromwell.

• Material - Components that are designed to enable or disable movement of a machine require a level of hardiness and durability for long-lasting design efficiency. Indexing plungers are commonly manufactured from stainless steel to guarantee protection against natural erosion as well as create a product that can withstand the natural force of constant movement. Handles, heads and knobs are usually crafted with a robust plastic for ease, comfort and sturdiness.

FAQs

What is the difference between a ring and knob indexing plunger?

The only difference between a ring and a knob indexing plunger is the head style. This is a choice that is made based upon the needs of the mechanism as well as the comfort of the user. Indexing plungers are most commonly manufactured with a head that is rounded and flat on the surface, resembling a rounded door handle, for easy push/pull movement. However, some are crafted with ring heads to engage the indexing plunger. There are also indexing plungers that are designed with a long handle to enable to the user to easily twist or turn the component.

What is a spring indexing plunger and how does it work?

An indexing plunger is a type of spring-loaded device (SLD) used to position, lock or index components. Indexing plungers are designed with a spring inside and as users apply pressure to the plunger or nose of the spring it forces the spring to compress and positions the component into the desired hole, groove or area.